Optical Emission Spectrometers

Optical emission spectrometers (OES) and the measuring principle of the atomic emission are the ideal method and provide the perfect instrumentation for metal analysis in all different industrial businesses and environments.

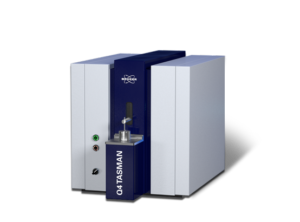

Q4 TASMAN Series 2

The new Q4 TASMAN Series 2 is an advanced benchtop spark-Optical Emission Spectrometer for the entire metals industry. With many improvements, it combines reliability and outstanding analytical performance with low cost of ownership.

Q8 MAGELLAN

Q8 MAGELLAN is a spark emission spectrometer setting new standards with respect to technology, reliability, flexibility, and handling. It is the first spectrometer worldwide that offers a previously unseen quality of analysis because of its unlimited combination possibilities of measurement parameters.

Q6 NEWTON

The Q6 NEWTON is the superior spark-OES solution for metallurgists and technicians to analyze alloy compositions of metals – with unparallel speed, precision and reliability. The Q6 NEWTON combines modern technology to challenge the data quality and speed of big floor standing systems.Metal producing industries like foundries, steel- copper-, aluminium plants, and all kinds of fabricators in the automotive, aviation, and home appliance industry, as well as inspection companies, contract laboratories and metal recyclers use optical emission spectrometers for process and quality control.

The optical emission spectroscopy is very well accepted due to its easy-to-use instrumentation. No matter if stationary, portable or mobile, these analyzers assure accuracy and highest precisions in all environments and for all tasks. Even in research and development laboratories they are convincing with their analytical performances.

Optical emission spectrometers cover the analysis of the chemical elements at the complete range from sub-ppm to percentage levels from pure metals trace analysis to high alloyed grades. All relevant elements can directly be analyzed simultaneously. The speed and the ease-of-use of this equipment make it so versatile and very well accepted and beneficial for operators. The robustness of the spark spectrometer allows the operation in all relevant situations for material inspection, alloy identification, and quality control.

High-quality spark spectrometers enable metal analysis for all metal industry process stages, from metal production through processing and recycling. Quality is guaranteed no matter what challenge or analytical task comes along.d