Layerava PEALD/ALE

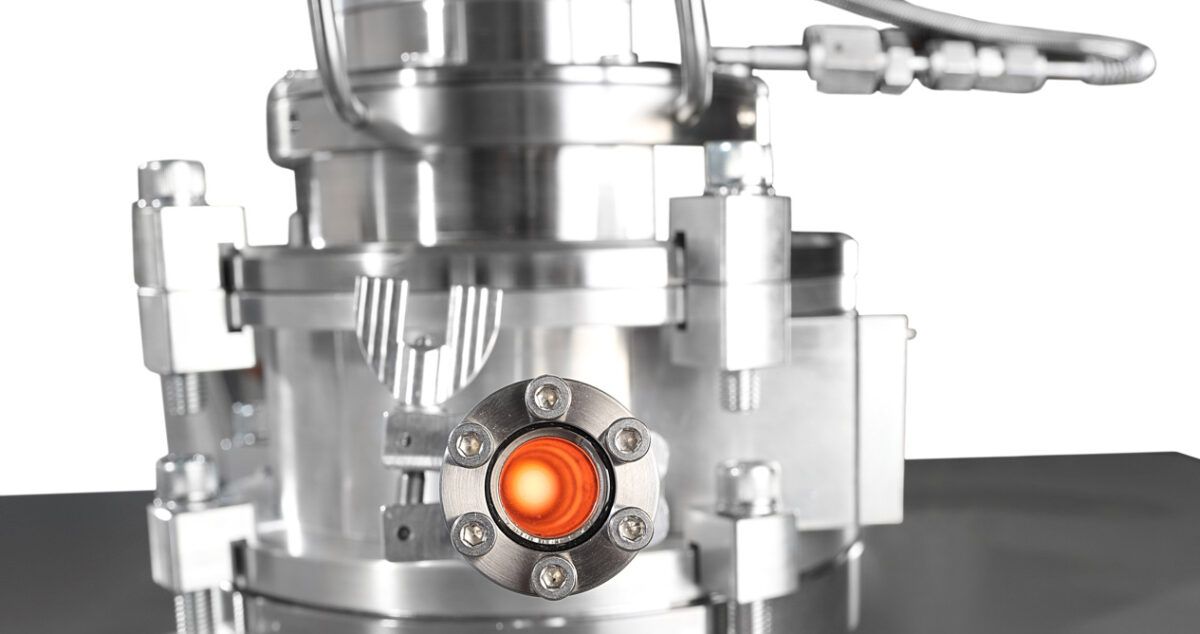

Layerava is a Hollow Cathode Plasma Enhanced Atomic Layer Deposition (HCP-ALD) system which is a versatile research tool designed for university and industrial research laboratories. Layerava is our PEALD + Thermal ALD capable platform. Plasma introduces an alternative energy source for the ALD surface reactions in addition to thermal energy. This increases the range of available chemistries with the introduction of various neutral radicals and ion species and result in denser film deposition.

Layerava platform has unique advantages in growing III-Nitrides (AlN, GaN, BN, InN, TiN, etc) with record-low Oxygen contamination in III-Nitride films. Our patented large-area hollow cathode plasma (HCP) and compact reactor design allow for the highest quality as-grown III-Nitrides with the lowest Oxygen content reported in the literature. Thanks to our patented reactor design, our recipe does not require the use of corrosive gases such as NH3 for the growth of III-Nitride films, but only common gases such as N2, H2 and Ar are sufficient. With such a highly efficient reactor design combined with the hollow cathode plasma source, III-Nitride films can be grown polycrystalline at temperatures as low as 200C.

The unique features of Layerava is providing amazing results in the growth of metal-oxide layers as well. The in-situ plasma annealing feature was shown to achieve as-deposited beta-phase Ga2O3 at record low temperatures as low as 200C.

Specifications

- Stainless steel reactor chamber

- MFC controlled four plasma process gas lines (N2, H2, O2, Ar)

- RF power supply and automatic matching network

- 250C substrate heating (320C optional)

- Substrate sizes 100mm, 200mm

- Swagelok high-speed ALD valves (4-8 ports)

- MKS MFC-controlled carrier gas

- Convection-enhanced Pirani vacuum gauge

- MKS pneumatic isolation valve

- Fully automated with recipe control

- User-friendly graphical user interface

- World-class scientific support team and recipe library

Customizations

- Powder ALD kit with rotating canister, conformal coating of granular substrates

- Ozone (O3) process kit, fully recipe integrated and computer controlled

- Glovebox integration

- Precursor cooling

- Low vapor pressure chemical delivery upgrade

- Dome-lid for 3D objects and non-standard substrates

- In-situ ellipsometer metrology upgrade

- In-situ QCM thickness monitor

- Custom vacuum ports for in-situ RGA and IR spectroscopy