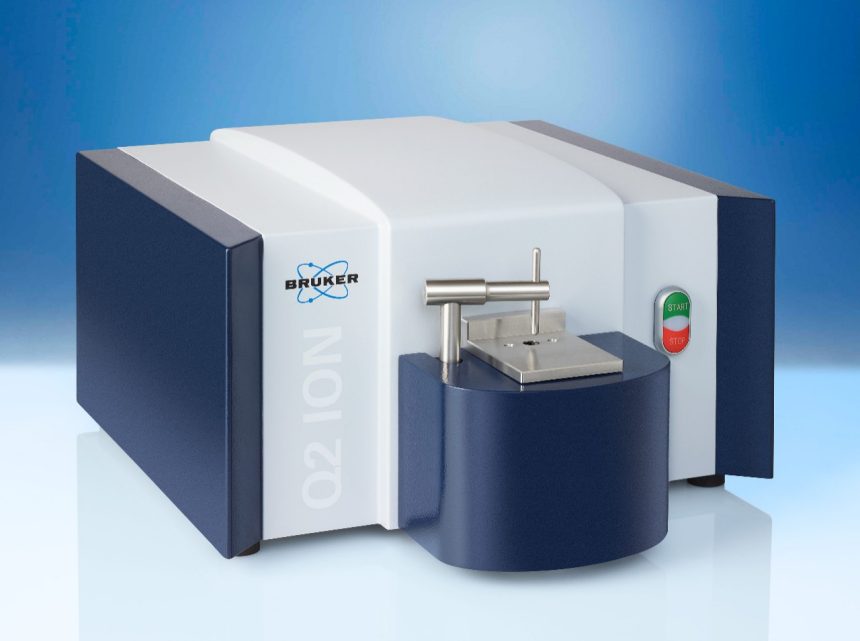

Q2 ION

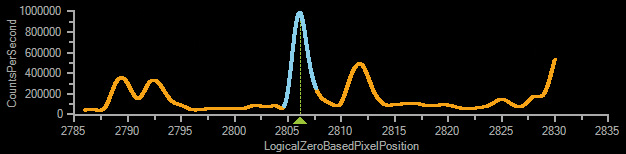

Ultra-Compact Metals AnalyzerPatented optical system with AAC

Incoming material inspection made easy

Ultra-Compact, portable Metals Analyzer

Instant Operation Readiness

by AAC (automatic ambient compensation)

The patented optical system with AAC compensates thermal drifts and provides maximum analytical stability without thermal conditioning.Intuitive Productivity

ELEMENTAL.SUITE

Our next generation OES-software, defines new standards in ease-of-use. Place your sample onto the spark stand and press the start button. In less than 30 seconds you get the complete composition of your metal and if needed the best match against the world’s reference alloy database.19 kg

true portability

The Q2 ION can easily be brought to a nearby site for analysis. Despite its low weight it is suitable for rugged environments.Q2 ION – Metals Analysis made easy

The new generation of spark spectrometer Q2 ION elevates metal analysis into new levels of simplicity and ease-of-use. Today it is one of the smallest and lightest ultra-compact spark emission spectrometer for metal analysis available. It is a versatile multi-matrix system for comprehensive incoming material inspection and quality assurance of metal alloys. Its primary applications and metal matrices include copper, aluminum and iron at smaller foundries, inspection companies, metal recycling and metal fabricators. An affordable price and exceptional low operational costs make this spectrometer the ideal tool for smaller and medium-size businesses.

Why do I need a compact spark-OES?

OES is the work horse in metal analysis par excellence. It gives you fast analysis of your solid metal samples including positive material identification, alloy grades and material sorting. The Q2 ION perfectly fits the requirements of foundries, fabricators, metal recyclers, warehouses and metal processing plants by combining ease-of-use with easy portability and low operation costs.

Key Benefits

Metal Industries

Steel, Iron and its alloys

A seamless quality control is essential in steel working. From scrap sorting, verification of incoming materials, quality assurance in the foundry process to end testing finished goods, the Q2 ION delivers the answers needed.

Aluminum

Aluminum is one of the most versatile materials for a broad range of applications running from soft, ductile wrapping foil to demanding engineering applications in aerospace. The recycling market represents a large volume of global aluminum production with the Q2 ION being an ideal solution for this industry.

Copper

Copper is the building block of many alloy types. The Q2 ION’s analytical solution pack with dedicated programs for seven alloy groups covers all major Cu analysis needs for fire-refined copper and its alloys.

Zinc

Zinc has a famous usage in corrosion-protection of low-alloy steels by galvanization but also the production of copper base alloys such as brasses, diecasting of small and complex mechanical parts, chemical applications and utilization of zinc foundry alloys are significant consumers. The Q2 ION provides a cost effective and easy-to-use solution for the quality control in these applications.

Tin

Tin is an important alloying element for copper alloys and solder materials with other main applications being production of tinplate and pigments for colors. In all cases an accurate alloy composition monitoring is required with the Q2 ION being a flexible and cost effective analytical choice.

Q2 ION Specifications

| Optical System | Un-coated CCD detector with lowest dark current Flat field grating Argon purged for best transparency ClearSpectrum technology for advanced spectra deconvolution Automatic Ambient Compensation (AAC) for operation between 10 and 45 °C (50 and 113 °F) |

| Source Generator | Maintenance-free, two phase PWM generator Frequency 50 to 1000 Hz Spark and arc-like discharges from 10 μs to 2 ms |

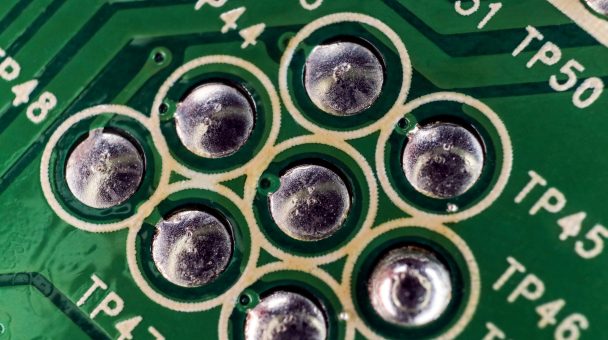

| Sparkstand | Nearly maintenance-free Low Argon consumption during measurement Argon quality 4.8 specified for spectrometry or better |

| ELEMENTAL.SUITE | Intuitive Windows® based software for simple routine operation Various user levels for secure and task-specific operations ELEMENTAL.SUITE software including analysis database and interfaces to MS Office Grade Library functions |

| Analytical Solution Packages (ASPs) | Different matrix calibration packages available ASPs cover all major elements and alloy groups Upgradable for future expansion |

| Electrical Data | 100 to 240 V (50/60 Hz) 200 W during measurement, 50 W during standby 16 A (240 V) or 25 A (100 V) slow blow fuse |

| Dimensions & Weight | Width 440 mm (17 inch) Height 220 mm (9 inch) Depth 390 mm (15 inch) Weight ~ 19 kg (~ 42 lbs) |

| Environmental conditions (operation) | Temperature 10 – 45 °C (50 – 113 °F) Humidity 10 – 90 %, no condensation |

| Available accessories | Wire adapter, tube adapter Sample preparation Carrying case Notebook or desktop PC |