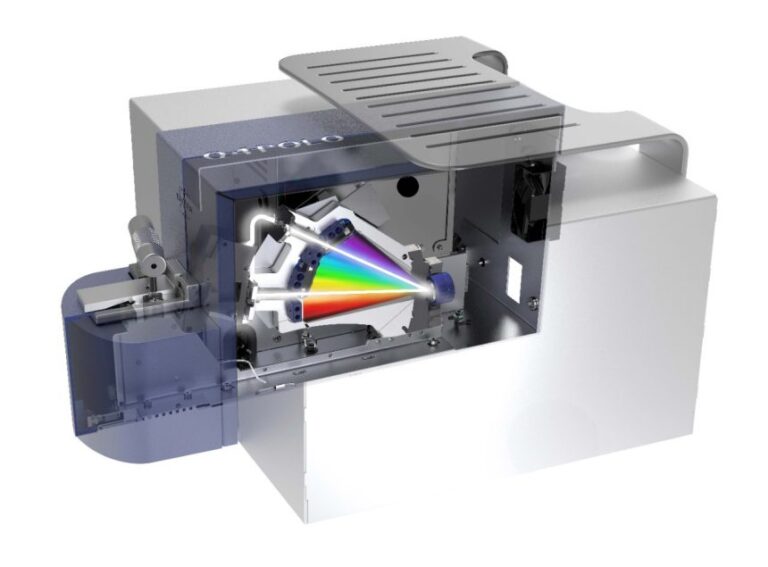

Q4 POLO

Compact multi-chip Spark SpectrometerThe Little Giant in Spark-OES

Complete Elemental Coverage, Wide Calibration Ranges

High Precision Metal Analysis with low cost of ownership and small footprint

AAC™

Autofocus Included

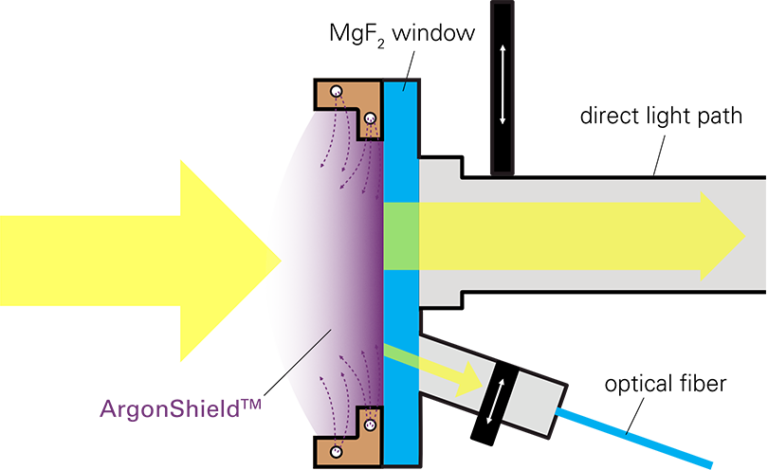

Bruker’s patented concept for self-focusing under temperature variations eliminates thermal drifts. The new ArgonShield™ prevents contamination of the optical window during measurements.130 – 785 nm

Wavelength coverage for comprehensive access to all relevant elements

The innovative MultiVision™ optics is equipped with a electromagnetic light junction to use the full elemental range with best performance and compactness.Intuitive Productivity

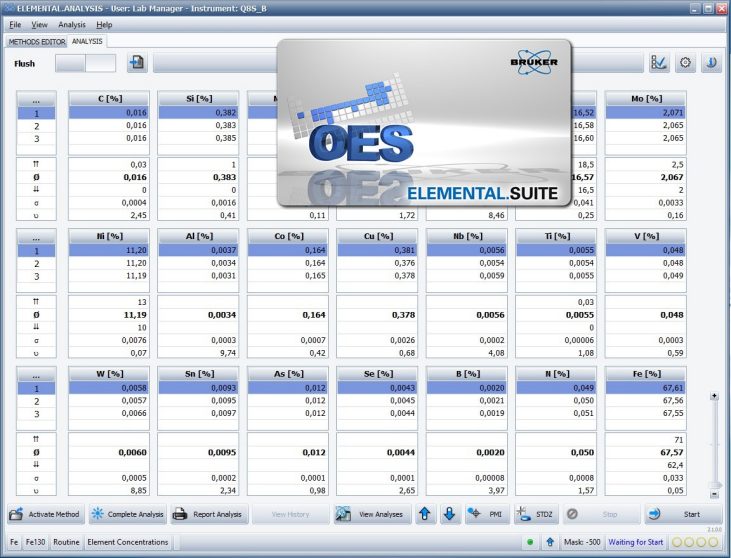

ELEMENTAL.SUITE

The insulated SafetyTip on the new sample clamp prevents incorrect sample positioning, and ensures safe operation for a wide variety of samples. Combined with ELEMENTAL.SUITE, our next generation OES-software, this leads to functionality with ease-of-use.RELIABLE, HIGH PRECISION ANALYSIS FOR EVERY FOUNDRY AND PRODUCTION FLOOR

Q4 POLO – Little Space, Mighty Performance

Numerous innovations have been introduced in the Q4 POLO to create a spark spectrometer that is second to none. In addition to superior analytical performance for a full range of elements, the Q4 POLO enables applications previously not addressable by such compact instruments:

- Outstanding precision, particularly on light elements

- Excellent results in the challenging analysis of cast iron

- Reliable analysis of nitrogen at low ppm levels in low alloyed steels

- Analysis of oxygen in copper

Just as impressive as the results achieved by the Q4 POLO is its incredible long-term stability. The absence of thermal- and contamination-based drifts reduces the need for cleaning and recalibrations, leading to stable results around the clock.

The new Q4 POLO is the ready-to-analyze solution from day one, covering all relevant elements and wide concentration ranges. Each base metal package includes all dedicated alloy groups, calibrations, and standardization samples. At the same time, the Q4 POLO provides high uptime, low maintenance, and hassle-free operation.

Key Benefits

- MultiVision™ optics with electromagnetic light junction covering the full elemental range with superior performance and small footprint

- AAC™ and ArgonShield™ result in incredible long-term stability without increasing argon gas consumption

- The new active sensing SmartSpark™ source is fully digital and equipped with detection of non-energetic discharges for increased precision and long-term stability

- ELEMENTAL.SUITE delivers highest functionality combined with ease-of-use for information @ your fingertips.

Why do I need a compact spark-OES?

OES gives you an ultrafast analysis of your solid metal sample without complications. All relevant elements are simultaniously determined.

What is your analytical challenge?

Iron & Steel

Processing steel requires precise and accurate results on incoming and outgoing materials over a wide variety of alloys, incl. N at trace level.

Aluminum

Mastering the phosophorous and alkali content in aluminum.

Copper

Copper is the building block of many alloy types. The Q4 POLO covers them all including oxygen determination.

Q4 POLO Specification

| Specification | Benefit | |

|---|---|---|

| Spark Stand | Low maintenance spark stand with co-axial argon flow, accessible from 3 sides | Minimized argon consumption, easy analysis of wires and small pieces, also accepting bulky samples |

| Sample Clamp | 80 mm sample height with exchangeable SafetyTip™ | Ensures correct sample positioning and safe operation for a wide sample variety |

| Smart Spark | Digital spark source for stable spark generation up to 1,000 Hz; active sensing of non-energetic discharges | Improved precision and long-term stability with highest operational safety |

| Optics | λ: 130 – 785 nm, argon purged, multiple un-coated linear array detectors with lowest dark current | Access to all elements, low operational costs |

| Optical Concept | Optimized in Paschen-Runge configuration, with high UV-C transparency and dual light paths | Field-proven robustness and precision with excelled light element performance |

| MultiVision™ | Electromagnetic light junction, switching between two light paths and three alternative plasma views | Compactness with superior optical resolution |

| AAC™(Bruker Patent1)) | Automatic Ambient Compensation keeps the optic focussed, eliminating thermal drifts | Incredible analytical stability, reduced maintenance or recalibration without need for air condition |

| Argon Shield™ | Prevents window contamination during measurements | Permanent transparency with minimized maintenance |

| Gas Supply with Argon-Saver Mode | Argon ≥ 99.998%purity2) (Ar 4.8) 3 bar (± 10%) supply pressure Copper tubing (6 mm o.d.) with Swagelok® fitting | Good performance with standard argon purity, dedicated argon saver mode for lowest operational costs |

| Noise Emission | < 55 dB(A) during measurement3) | Enjoy the silence |

| Electrical Data | 100 – 240 VAC (±10%), 50 – 60 Hz 10 – 16 A (240 V), slow blow fuse 200 VA (max), 20 VA standby, typically: 95W(@ 230 VAC) during measurement | Compatible with all worldwide power and current configurations |

| Dimensions & Weights | 49 x 57 x 28.4 cm (W x D x H), ~36 kg | |

| 1) US8891082B2, EP2537011B1 2) Argon 5.0 or purifier recommended for trace nitrogen analysis 3) Sample covering hole in sample stage completely |