Q8 MAGELLAN

High-End Optical Emission Spectrometer for Metal AnalysisMastering impurities & inclusions

Single-button operation

High-end spark-OES spectrometer for primary metal process- and quality control

Pure PMT-based performance

with Single Spark Evaluation (SSE)

Unleashing the speed of the latest Photomultiplier tube (PMT) detectors for compelling analytical performance including analysis of non-metallic inclusions.750 mm

focal lengths

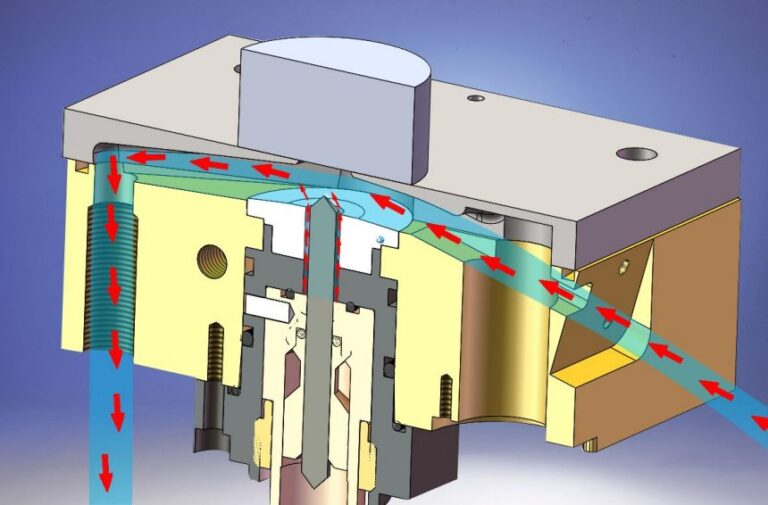

Paschen-Runge mount with holographic grating delivers stability and resolution.110-800 nm

wavelengths coverage in a high-vacuum optics

Ensure ultimate UV performance, analytical stability without gas purge and flexible PMT configuration to master your analytical challenges.High-end PMT performance combined with robustness and low operational costs

The new generation of the Q8 MAGELLAN spectrometer is setting new standards with respect to stability, flexibility, ease-of-use and analytical functionality for the elemental analysis of metals. Each Q8 MAGELLAN is tailor made to match your current and future requirements by an optimal selection from >200 available analytical channels: single or multi-base applications, trace analysis or alloys, the Q8 MAGELLAN can be configured to master virtually any metal analysis task.

Key Benefits

- 100% PMT-based performance supported by a digital plasma generator for unlimited time resolution incl. SSE and inclusion analysis

- High-vacuum optics ensures optimal performance without argon purge

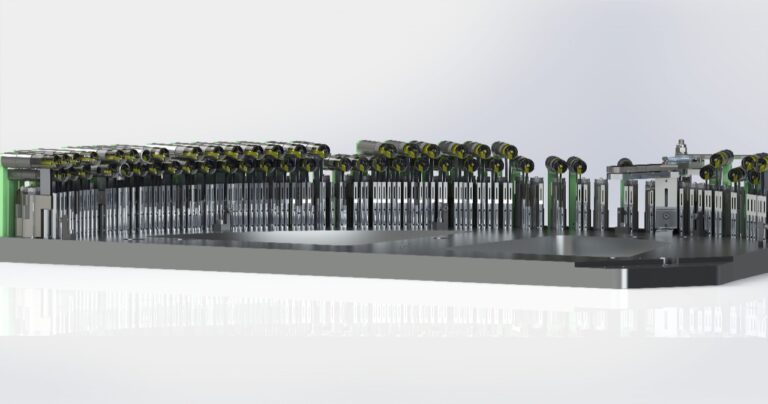

- Heavy-Duty, low maintenance spark-stand with co-axial argon flow

- Automatic sample clamp ensures fast and reliable one-button operation

- ArgonStopTM means no argon consumption during breaks with reduced start-up times and improved analytical performance on small samples and thin wires

- True factory calibration with reference materials, evaluated by an expert to ensure highest accuracy and analytical quality

Fully automated Online Metals Analyzer

The Q8 MAGELLAN online is prepared for integration in customer specific automation projects to form a fully automated analysis system tailored to the individual needs of process analysis for steels, cast iron, aluminum and copper.

Quality Metal Analysis

Iron & steel alloys, incl. impurities

Steel producers need reliable, precise and accurate results, in a short time with low running costs. Unreliable results lead to faulty batches with cost intensive rework. The Q8 MAGELLAN with its high vacuum optic delivers the stability and performance that primary metal producers and fabricators look for.

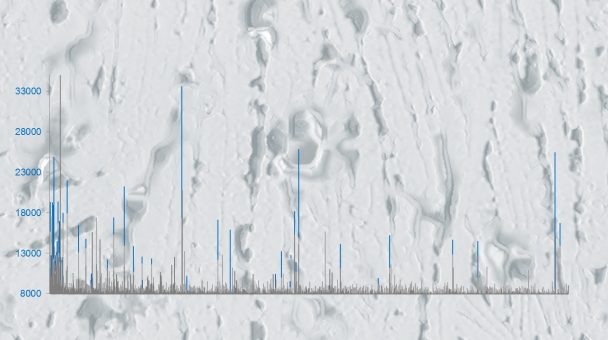

Inclusion analysis in steels

The demand for cleaner, higher-quality steels increases continuously. Non-metallic inclusions like oxides or sulfides play an important role for the steel cleanliness. Key to premium products are lowest oxygen levels and best steel cleanliness degrees. With its SSE-capabilities and the “Metal-Cleanliness-Inspection” package, the Q8 MAGELLAN provides important quality indicators seamlessly.

High-Purity copper

The analysis of high purity copper requires reliable sub-ppm determination of metallic and non-metallic impurities and thus extremely low detection limits combined with highest accuracy. The Q8 MAGELLAN masters these demanding requirements by using its superior PMT detectors in a high-vacuum optical system in a dedicated high-purity copper configuration.

The Q8 MAGELLAN is the ultimate choice for all kind of non-ferrous metals

– Aluminum & Magnesium alloys and impurities – Nickel & Cobalt alloys and impurities – Lead, Tin & Zinc alloys and impurities – Copper & Titanium alloys and imputities – Precious metals (on request, subject to sample availability) including demanding tasks like:

– Oxygen in copper

– Nitrogen in steels

Q8 MAGELLAN Specifications

| Optical System |

|

| Read-out system |

|

| Instrument control |

|

| Source |

|

| ELEMENTAL.SUITE |

|

| Electrical Data |

|

| Weights & Dimensions |

|